|

| Size comparison (typical 1920's Meccano pose!) |

During the time that the Krupp 288

bucket-wheel excavator has been in complete form in my house in Grahamstown it

has attracted many visitors, from among both locals and visitors to our town,

as well as a fair amount of national and international media interest,

resulting in various articles and videos. A universal comment has been that the

model should be on display to a much wider audience. Our small town (with a

population of about 100,000) is an educational centre, with several schools, both

private and state, a university (Rhodes University) and Technical College and

is the centre of a farming community. Physical exposure of Bagger 288 is

therefore relatively limited.

Accordingly, I have decided to put

the model on the market, targeting museums of technology, mining, science,

toys, etc. I am prepared to pack the

components of the model in specially designed crates for safe transport by road

or sea. I am willing to consider any

reasonable offer as payment. Interested

parties can contact me as per information on this blog site.

Building Bagger 288 has been a

great challenge and very exciting to me.

One quickly forgets the tedium (and strain on hands and arms!) of making

tens of thousands of parts when one sees the end result come to life powered by

its 55 electric motors

I have thus decided to build

another excavator in replica Meccano, again making all the parts myself with

the help of the same people who supported my BWE! This time I want to build the Marion 6360 stripping

shovel, which worked in the Captain Mine in Illinois from 1965 to 1990. When it was built it was the largest land-based

fully mobile object in the world (this title was taken away by the German

240,000 cubic metre per day bucket wheel excavators – BWEs - like Bagger 288)

The principle of the stripping

shovel is completely difference from that of the BWE. In the former, a single large bucket is

rammed into the work face by a crowd mechanism, as it is known in the

industry. The Marion 6360 was the

largest such machine ever built, with an all-out weight about 1000 tons lighter

that the German BWEs. Only one was

built. It came to a sad end in 1990 when

a fire broke out, thought to have been caused by a ruptured hydraulic line

spraying into live electrical power boards. A substantial amount of grease had built up in

the lower works of the machine over the years and this burned fiercely for

about a day. The crew escaped unhurt but

fire teams were unable to extinguish the blaze because of the remote part of the

mine in which machine was working, and the difficult terrain. Immense damage was done and it was deemed

uneconomical to try repairing it. It was

scrapped din 1992.

My model of the 6360 will be on the

same scale as the BWE, 18 to 1, giving it a height of 12 feet and width of

about 4½ feet. Project mass is in the

region of 1000 to 1100 Kg. so it is slightly lighter than the BWE (at 1335

Kg). It also takes up less space that

Bagger 288 being a more compact ‘chunkier’ machine. The working length will be about 17 or 18

feet with dipper arm fully extended. It

will fit in a double garage which I have, which has a high ceiling (as does my

lounge). In fact I sold a collector’s

piece motor car, a BMW 3.0 CSL, in order to have the space to build the model

and finance it! I think Meccano models

are a more controllable expense than restoring old cars. I had planned to get the BMW into concourse

condition during my retirement by have decided that Meccano models are a bigger

challenge and more fun!

With funds from the sale of the car

I have been able to have all the parts for the 6360 laser cut at the outset and

thus negotiate good prices. The drilling

is going well (about ¾ complete) and the first of the eight crawler units is

complete and running. Most of the brass and aluminium parts have been turned as

well. I have included some photographs

of it as well as some new views of Bagger 288 taken by my wife from a different

angle. The Marion crawlers are larger than the BWE ones since there are only

eight as opposed to fifteen on the BWE.

|

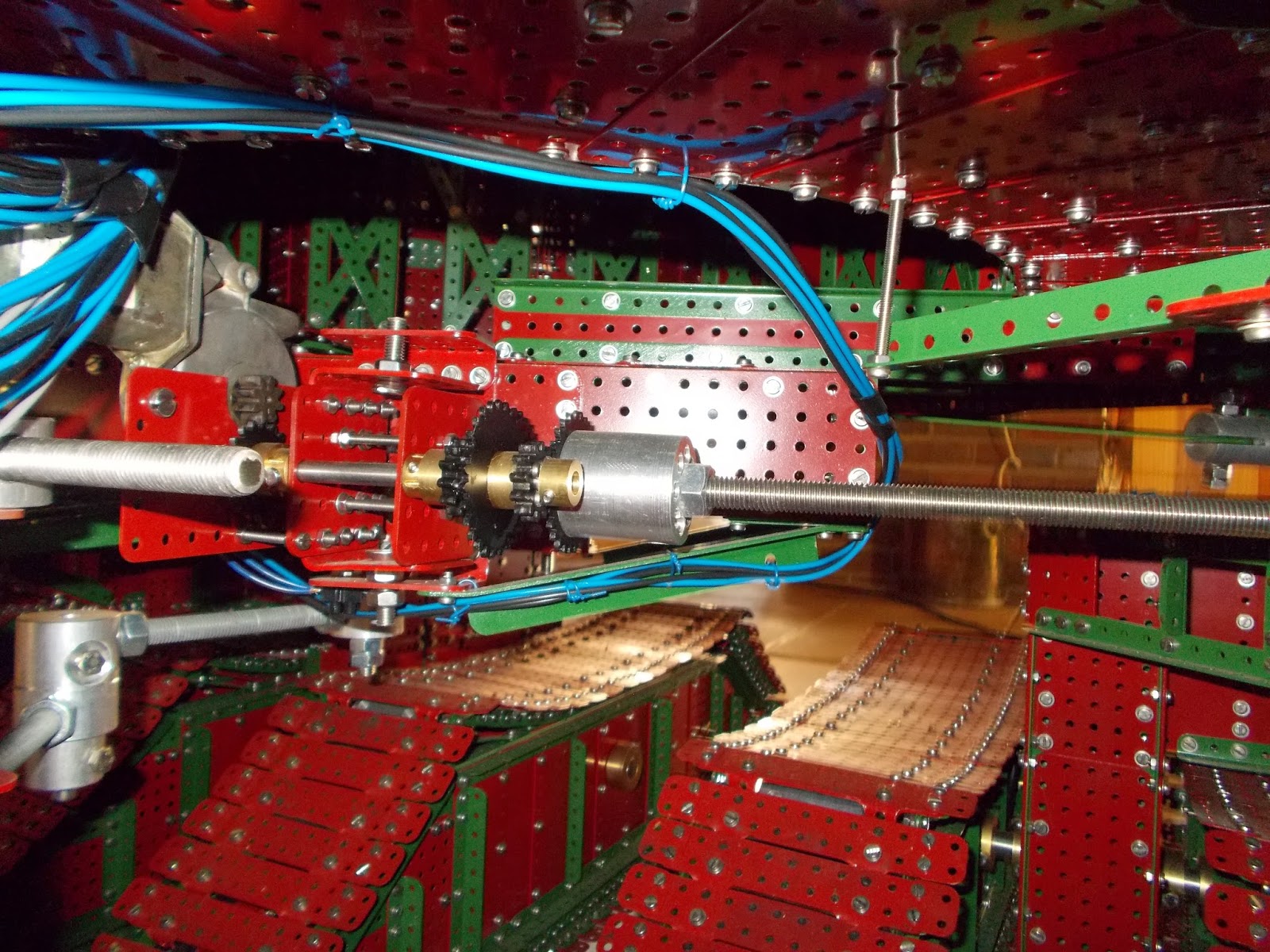

Below are pictures of the beginning of the new project: Marion 6360 crawler: