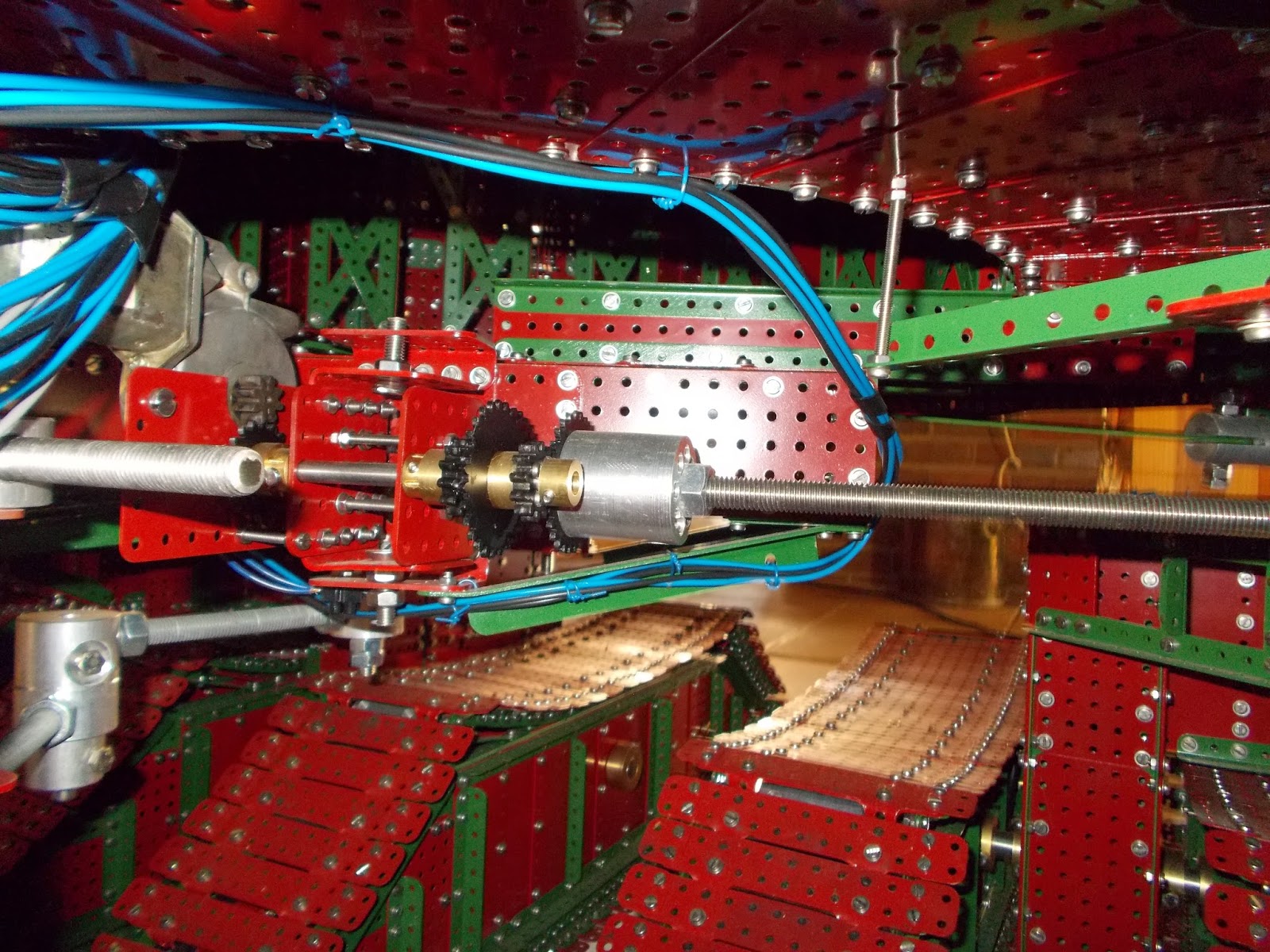

A video clip (about 6 minutes) of

the model

has now been made

(by Neil Shaw, an independent film-maker from

Cape Town) showing the various motorisations working (traversing back and

forth, slewing of upper arms, raising and lowering of bucket when arm rotation

of bucket wheel, and all 6 conveyor belts running (including static conveyor of

20 foot).

All the minor movements

(accuated with a total of sixteen 6 volt Meccano motors) are also featured (5

service cranes, and up and down movement of front driver’s cabs).

This clip is now owned by AP (Associated

Press) and will be sold to about 300 TV stations worldwide.

These stations then have the right to edit

the clip for their own use.

A short version (about 1 minute) has already appeared on YouTube.

I am happy to say that the final

assembly went well with no mishaps.

Stage one was to lift the central unit onto its crawler system. This was done as follows: first the wooden lifting cradle was attached

to the three upper protruding M20 bolts which go down into the crawler bridge

units. This was then lifted (by 8

people, as the combined unit now weighed over 240kg) onto two strong A-frames,

which in turn rested on eight stacks of 2-high bricks. This allowed enough room under the M20 bolts

to slip the bridges on from underneath and to bolt up with M20 locknuts from

below (once three 65mm diameter brass spacers had been slipped into place, to

get the correct distance between bridges and vertical finlike structures on the

outside of the main unit.) These brass fittings had cuplike voids machined out

on one side to accommodate the locknuts.

This ensured that flat surfaces on the bridges remained parallel with

flat surfaces below the fins. This had

the effect of helping to keep the bridges from buckling forward or backward. Of

course, for such buckling to occur, the M20 bolts would have to bend quite

seriously. This is not likely, as they are high tensile.

At this stage the whole structure

had to be lifted by the 8 lifters and held while the bricks were removed from

under the A-frames, a rather tense interval.

When the cradle was replaced on the A-frames there was just enough room

to slide the twelve main crawler units sideways onto their M20 rocker axles

protruding from the bridges. Large brass

collars then locked them securely in place.

With the crawlers and bridges

securely in place the whole central unit weighed more than 500kg. This was too heavy for even for 8 lifters so

the final downward trip of about 1 inch was done using my 2-ton hydraulic car

jack and some supporting timber, first at one end of the cradle and then the

other. For the first time the central

unit was on its “feet” and mobile. The

24 cores to the 12 motors were connected to a 12 volt source and the crawler

system and found to be satisfactory (before the final lowering onto the ground

I had been very careful to check all motor polarities – to have one motor

trying to work against the other 11 would be very rough on the works!)

The next big task for the lifting

team was performed a week later and involved fixing the main horizontal arms in

place. First the rotating upper toroidal

ring had been put in place on its roller race of 65 brass flanged wheels. A set of 6 locking flanged wheels had been

put in place on three strong vertical arms which came up the inside of the

upper torus. These wheels roll on

another roller race on the top of the upper torus. Their purpose is to prevent the whole upper

machine from toppling over, should any unforeseen accident occur (the machine will

sit on a vertical surface for its lifetime and is well-balanced even if slight

tipping happens, having a low centre of gravity in relation to the main

support).

The first arm to be attached was

the counterbalance. This had already been bolted to the heavy central

triangular frame of box girders by means of four M10 bolts into heavy straps

(rather than multiple M4 bolts, since the angles were not 90°, as explained elsewhere). My helpers carried the 140 kg arm over and

lifted it into place on some wooden scaffolds (since the winding drum end

needed to be over 8 feet off the ground.

There were some anxious moments

for me as the four 12mm holes drilled on the bottom of the box girder frame

came down on four M12 bolts protruding from the upper ring. This match had not been tested before, as the

separate parts were too heavy for me to move around on my own. Fortunately the fit was good. I must admit that I had a 14mm drill bit on

standby on my portable drill in case I had to ream a 12mm hole out to 14mm!

Once the counterbalance arm had

been bolted in position the bucket wheel arm could be brought over and two M12

bolts slipped into place to act as pivots on which this arm can move (to change

the height of digging wheel). Again, the fit had not been tested, due to the

enormous weight, but all went together smoothly. Several of the bolts in critical places on

the two components had been replaced by countersunk bolts (into 2mm plate) to

avoid bolthead clash as the bucket wheel arm moved. This turned out to be a wise move. So ended the day’s work with the horizontal

arms resting on trestles at their outer ends.

The next main stage was the upright

arm placement. To be safely accomplished

this required some serious scaffolding.

I had made the components ahead of time and now they needed to be

erected: two 9 foot high scaffolds were built, one on either side of the model,

during the next 2 weeks.

On the day of the fitment my

helpers passed each 45kg upright arm up handlers sitting on top of the 9 foot

scaffolds. From there they were lowered and M10 bolts put through lugs on the

arms and on the waiting model below. All went well except I put an upright on

back to front! It had to be turned around and re-bolted. At this stage the

upright arms were held in place by wooden struts bridging the gap between

scaffolds.

Over the next week or so the 2mm

braided steel wires were run onto the large winding drums and around the

thirty-four 4 inch aluminium pulleys atop the two upright arms. The fixed length 8mm threaded rods were

slipped into their retaining blocks and lock-nutted. The winding drums were then started and the

cables brought into tension so that the whole model became

self-supporting. By trial and error it

was determined that the balance of the model was optimum when 35kg of concrete

blocks were placed under the winding drum area.

All motions could now be tested:

traversing, slewing, raising and lowering the bucket wheel, running all

6 conveyor belts, bucket wheel rotation, all motions of the 5 service cranes, the up

and down movement of the 2 drivers’ cabs and the motorised positioning of the

final output chute over the static conveyors.

All now works.

Engineering on the models appears

to have been adequate. As a precaution

against the finlike structures trying to splay outwards under load (thus

deforming the large toroidal frame out of round) I installed 3 heavy straps at

the bottoms of the fins and meeting in the central point with a M8 bolt.

However, the tension in these has not increased at all after fully loading the structure,

indicating that the engineering is adequate (no measureable deformation).

The mass of the model has now

been accurately calculated to be 1335kg.

This calculation was done with the help of my friend Prof Perry Kaye,

retired professor of chemistry at Rhodes University. He accurately weighed each of the most

commonly used basic parts on a chemical balance and I was then able to

calculate the number of each part used by subtracting what was left over from the

total made.

To the best of my knowledge this

makes “Bagger 288” the largest Meccano model in the world. I have not been able

to find one of greater weight anywhere.

The Ripley’s Museum Ferris wheel (which they claim is the largest

Meccano model in the world) has a mass of 544kg. Purists will claim that my model is not Meccano because of the heavy gauge

versions of Meccano parts used, but to the best of my knowledge the Ferris wheel

is also not pure Meccano, as, for safety reasons, it had to be re-engineered,

with all its Meccano strip spokes replaced by 8mm stainless steel rods. The fact remains that it is not possible to

build a model of this size in Meccano without some heavy gauge adaptation,

especially if the model is as mobile and articulated as a bucket wheel

excavator. My philosophy was to rank

engineering safety as first priority, followed closely by architectural

accuracy. I wanted to avoid any

retrofitting, due to a collapse due to engineering inadequacy.

In conclusion, I must express my

grateful thanks to the members of the lifting team.

|

| Dr Jennifer Williams, Prof John Williams, Dr Kevin Lobb, Andrew Shepherd, myself, Tim Bull, Landman Bester, Charlie O'Donoghue, Jessica Harris, Alexander, Richard Grant, Stefan Just |

.JPG)